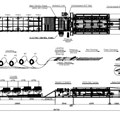

Fully automated machine system

This fully-automatic system is specially designed for the production of rectangular air ducts, with profiled PDF frame flange, up to a width of 1,500 mm. 1 worker needs about 1 - 1 1/2 minutes to produce the final product , dependce on the flang type (closed Pittsburgh-seam and stiffened rectangular duct with profiled PDF 3 frame flange, size 500 mm x 500 mm). All PDF flange systems can easily reach leakage class „C“. Our special PDF 3 system achieves even leakage class „D“ (from major European customer tested and approved).

Technical data

- Material: 0,6 - 1,2 mm galvanized steel

- Duct types: Full box, U, L, I - pieces

- Minimum duct size: 150 x 200 mm

- Coil width: 1.500 mm

- Maximum coil weight: 5.000 kg

- Maximum coil diameter: 1.000 mm

- Stiffening: Z-stiffening

- Crossmoving pittsburgh cassette

- PDF flange height:

- 20 mm -> 0,6 - 0,8 mm

- 30 mm -> 0,9 - 1,2 mm

-

Stations:

- PDF 1 = 14 stations

- PDF 1 Super = 18 stations

- PDF 2 = 18 stations

- PDF 3 = 27 stations

Highlights

- Closed duct with integrated PDF flange

- Finished Duct in approx. 60 seconds

- Reduction of labour costs

- No purchase of slide-on-flanges

- Automated folding and seam closing unit

- No wrong assembly at frame manufacturing

- Notches for stiffening rods

- Injection of sealing compound into the pittsburgh seam

- Roll closing system

Download brochure (PDF)

Ask for offer